Introduction

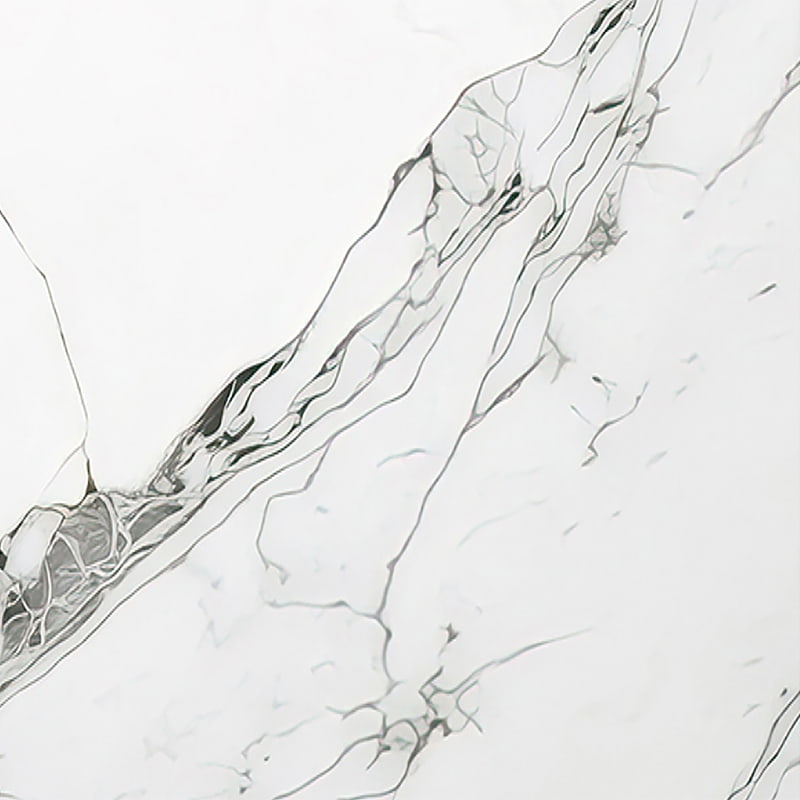

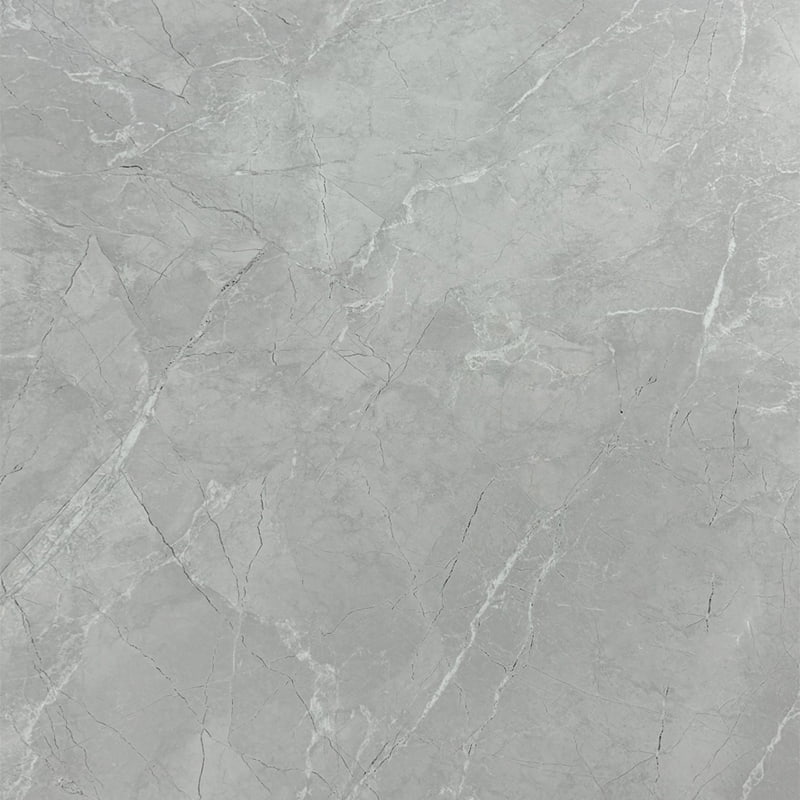

In recent years, UV mable sheet has emerged as a versatile material in both residential and commercial spaces. Known for its lightweight properties, water resistance, and customizable surface designs, it offers an attractive alternative to traditional marble and other decorative wall panels. The innovation of digital UV mable sheet has further expanded its applications, allowing designers and architects to achieve intricate marble-like textures and patterns without the constraints of natural stone.

Unlike traditional stone, UV mable sheet combines advanced coating technology with precision printing to replicate the elegance of marble while offering practical benefits such as easy maintenance, reduced installation time, and environmental sustainability. From kitchens and bathrooms to office spaces and hotel lobbies, UV mable sheet is increasingly being recognized as a material that balances aesthetic appeal with functional performance.

What is UV Marble Sheet

UV mable sheet is a type of decorative panel that replicates the appearance of natural marble using advanced UV coating technology. Unlike traditional marble, which requires heavy installation and maintenance, UV mable sheet is lightweight, easy to handle, and can be applied to walls, ceilings, and furniture surfaces. The production process involves applying a UV-cured coating onto a substrate, often PVC or engineered panels, followed by high-resolution printing to create realistic marble patterns. This combination of coating and printing ensures durability, water resistance, and resistance to scratches or stains.

One of the key advantages of UV mable sheet is its flexibility in design. Digital UV mable sheet allows manufacturers to create complex textures and color variations that are difficult or impossible to achieve with natural stone. This digital process makes it possible to produce custom patterns for high-end interior projects, giving architects and designers almost unlimited creative freedom.

In addition, UV mable sheet offers environmental benefits. Since it is made from engineered materials rather than quarried stone, it reduces the environmental impact associated with mining and transporting heavy natural marble. Its low maintenance requirements also contribute to sustainability, as less cleaning chemicals and effort are needed over its lifecycle.

Comparison Table: Material Characteristics

| Material Type | UV Marble Sheet | Natural Marble | PVC Faux Marble | Coated Panels |

|---|---|---|---|---|

| Weight | Light | Heavy | Light | Medium |

| Water Resistance | High | Medium | High | Medium |

| Fire Resistance | Can be fire-retardant | Natural | Can be fire-retardant | Medium |

| Maintenance | Low | High | Low | Medium |

| Customization | High (patterns/textures) | Low | Medium | Medium |

Main Application Areas

- UV mable sheet is popular due to its combination of aesthetic appeal and functional properties.

- Versatile for both residential and commercial projects.

- Digital UV mable sheet allows greater customization and design options.

Residential Applications:

- Used in kitchens, bathrooms, and living rooms.

- Water-resistant and easy-to-clean surfaces.

- High-gloss finishes and realistic marble textures enhance interiors.

- Often applied as feature walls or backsplashes.

Commercial Applications:

- Common in hotels, offices, and shopping malls.

- Achieves luxurious look without high cost or structural issues.

- Customizable patterns create sophisticated spaces.

Engineering & Public Projects:

- Used in schools, hospitals, and airports.

- Lightweight, fire-retardant, and easy to install.

- Balances functionality and visual appeal.

Comparison of Applications and Key Features

| Application Area | Recommended Features | Advantages | Typical Uses |

|---|---|---|---|

| Residential Kitchens/Bathrooms | Water-resistant, easy-to-clean | Low maintenance | Wall panels, backsplashes |

| Commercial Spaces | High-gloss, customizable patterns | Elegant appearance | Hotel lobbies, office walls |

| Public Buildings | Lightweight, fire-retardant | Safe and convenient | Schools, hospitals, airports |

Technology and Product Analysis

The technological advancements behind UV marble sheet have transformed it from a simple decorative material into a highly versatile solution for modern interiors. The core process involves applying a UV-cured coating to a substrate, typically PVC or engineered boards, followed by digital printing to replicate the textures and colors of natural marble. This method ensures consistent quality, precise patterns, and a durable finish that can withstand everyday wear and tear.

Material and Surface Effect Comparison

| Feature | UV Marble Sheet | PVC Marble Sheet | Coated Panels |

|---|---|---|---|

| Surface Finish | High-gloss, matte, custom textures | High-gloss, matte | Matte, basic textures |

| Water Resistance | High | High | Medium |

| Fire Resistance | Can be fire-retardant | Can be fire-retardant | Medium |

| Pattern Customization | High | Medium | Low |

| Suitable Environments | Multiple interior scenarios | Indoor wall surfaces | General interior decoration |

Application Case Analysis

- Versatile Applications: Used in residential, commercial, and public projects due to aesthetics, functionality, and easy installation.

- Residential Use: Ideal for kitchens and bathrooms; water-resistant, easy-to-clean, with high-gloss finishes and realistic marble patterns; often used as backsplashes or feature walls.

- Commercial Use: Popular in hotel lobbies, offices, and retail spaces; digital UV marble sheet allows customized patterns and large panels; lightweight and fire-retardant for safe, striking interiors.

- Public/Institutional Use: Suitable for schools, hospitals, and airports; used for wall cladding, decorative surfaces, and partitions; durable, lightweight, water- and fire-resistant for high-traffic areas.

Comparison of Functional Features by Application

| Use Case | Water Resistance | Fire Resistance | Lightweight | Decorative Effect | Ease of Maintenance |

|---|---|---|---|---|---|

| Residential Kitchens/Bathrooms | High | Medium | High | High | High |

| Commercial Spaces (Hotels, Offices, Malls) | Medium | High | Medium | High | Medium |

| Public Buildings (Schools, Hospitals, Airports) | Medium | High | High | Medium | High |

Design and Aesthetic Trends

The design possibilities of UV marble sheet continue to expand as digital printing technology and surface treatment methods evolve. Digital UV marble sheet allows for intricate patterns, realistic veining, and customized color palettes, enabling designers to create unique, visually compelling interiors. From high-gloss finishes to subtle matte textures, the material can replicate the look of natural marble or produce entirely new designs tailored to specific aesthetic requirements.

Comparison of Surface Effects and Design Options

| Feature | High-Gloss Finish | Matte Finish | Custom Texture | Color Customization |

|---|---|---|---|---|

| Reflectivity | High | Low | Variable | High |

| Visual Depth | Medium | Medium | High | High |

| Maintenance | Easy | Easy | Medium | Medium |

| Design Flexibility | Medium | Medium | High | High |

| Common Uses | Feature walls, kitchen backsplashes | Wall panels, furniture surfaces | Custom projects, artistic spaces | Bespoke interiors, branding |

Production and Supply Chain Trends

The production and supply chain of UV mable sheet have evolved significantly, driven by technological innovations and market demand. Modern manufacturing processes emphasize precision, efficiency, and sustainability, ensuring that panels meet high standards for appearance, durability, and environmental compliance.

Comparison of Production and Supply Chain Features

| Feature | UV mable sheet | Natural Marble | PVC Faux Marble | Coated Panels |

|---|---|---|---|---|

| Production Precision | High | Medium | Medium | Medium |

| Waste Generation | Low | High | Medium | Medium |

| Transportation | Easy, lightweight | Heavy, high cost | Easy | Medium |

| Installation | Simple | Complex, requires heavy support | Simple | Medium |

| Environmental Impact | Low | High | Medium | Medium |

Consumer Buying Guide

When selecting UV mable sheet for a project, consumers should consider a variety of factors to ensure the chosen product meets both aesthetic and functional requirements. Understanding the material’s characteristics, surface options, and installation requirements is essential for achieving optimal results.

Material and Surface Considerations

UV marble sheet is available in a range of finishes, including high-gloss, matte, and customized textures. High-gloss surfaces enhance brightness and visual depth, making them ideal for feature walls and decorative panels, while matte finishes provide a more subtle, modern appearance. Digital UV mable sheet allows for bespoke patterns and color variations, giving designers flexibility to match interior themes or branding requirements.

Functional Features

Key functional attributes include water resistance, fire-retardant properties, and durability. Water-resistant panels are essential for kitchens, bathrooms, and other moisture-prone areas, while fire-retardant variants are recommended for commercial or public spaces to comply with safety regulations. Scratch-resistant surfaces maintain their aesthetic appeal over time, and lightweight panels simplify handling and installation.

Installation and Maintenance

Ease of installation is another important consideration. UV mable sheet can typically be cut and mounted with standard tools, reducing labor time compared to natural marble. Maintenance is minimal; regular cleaning with a soft cloth and mild detergent is usually sufficient to maintain the finish. For high-traffic areas, periodic inspection of edges and surfaces ensures long-term durability.

Key Factors for Choosing UV Marble Sheet

| Factor | Considerations | Recommended Options |

|---|---|---|

| Surface Finish | High-gloss, matte, textured | Choose based on design and visual effect |

| Pattern Customization | Standard, bespoke | Digital UV mable sheet for personalized designs |

| Functional Requirements | Water resistance, fire-retardant, scratch resistance | Select panels suited to project environment |

| Weight & Installation | Light vs. heavy | Lightweight panels for easier handling |

| Maintenance | Ease of cleaning and durability | Low-maintenance surfaces preferred for high-traffic areas |

Conclusion

UV mable sheet has established itself as a versatile and innovative material in modern interior design. Combining aesthetic appeal, functional performance, and technological advancements, it offers an attractive alternative to traditional marble and other decorative panels. The emergence of digital UV mable sheet has expanded possibilities, allowing for highly customizable patterns and textures that meet the demands of both residential and commercial projects.

Its applications are broad, ranging from kitchen and bathroom walls to high-end commercial lobbies and public buildings. The material’s lightweight nature, water resistance, fire-retardant options, and ease of maintenance make it suitable for diverse environments, balancing practicality with design flexibility. The ability to replicate the elegance of natural marble without the associated weight, cost, or installation challenges has contributed to its growing popularity.

EN

EN English

English  русский

русский  Español

Español  عربى

عربى