Why Traditional Building Materials May No Longer Be Enough

Limitations of Traditional Materials in Modern Construction

Traditional building materials like gypsum board, basic drywall, wood panels, and PVC boards were once the standard for residential and commercial buildings. However, as construction standards evolve, these materials increasingly struggle to meet modern demands. Thermal insulation, fire resistance, structural durability, moisture resistance, and environmental sustainability are now crucial criteria. Traditional materials often fail in one or more of these areas, resulting in higher energy costs, frequent maintenance, and potential safety hazards. For instance, wood panels may warp or rot under humid conditions, gypsum boards can crack over time, and PVC panels offer limited fire resistance. As construction projects grow in scale and complexity, material selection has become more critical, and innovative solutions like Carbon Crystal Panel are gaining attention for their ability to address these shortcomings effectively.

- Insufficient insulation, leading to higher heating and cooling expenses.

- Susceptibility to moisture damage, mold, and warping.

- Limited fire resistance, posing safety risks in high-occupancy buildings.

- Short lifespan, requiring frequent maintenance and replacement.

- Environmental concerns due to non-sustainable material sourcing.

Growing Demands: Insulation, Fire Safety, Durability, and Sustainability

Modern construction projects require materials that perform efficiently over time. Energy-efficient insulation reduces utility bills, while fire-resistant materials safeguard occupants and property. Durability ensures long-term structural integrity, reducing maintenance costs and downtime. Additionally, environmentally friendly materials contribute to sustainable development goals and lower carbon footprints. As urbanization accelerates and building codes become stricter, there is a clear demand for materials that combine multiple performance criteria without compromise. Carbon Crystal Panel is designed to meet these needs, offering high insulation, superior fire resistance, and structural strength in a single solution.

- Enhanced thermal insulation reduces energy consumption and stabilizes indoor temperatures.

- Fire-resistant properties protect buildings and meet modern safety regulations.

- Durable construction materials minimize renovation and repair frequency.

- Lightweight yet strong panels reduce structural load and simplify installation.

- Sustainable material composition aligns with green building initiatives.

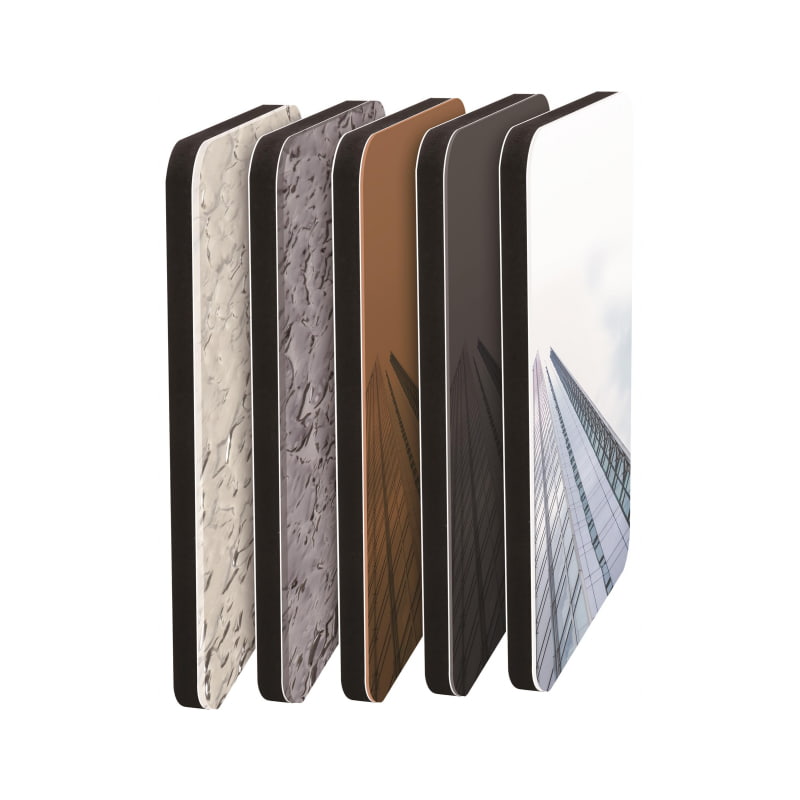

What Is a Carbon Crystal Panel? – Introduction to the Technology and Composition

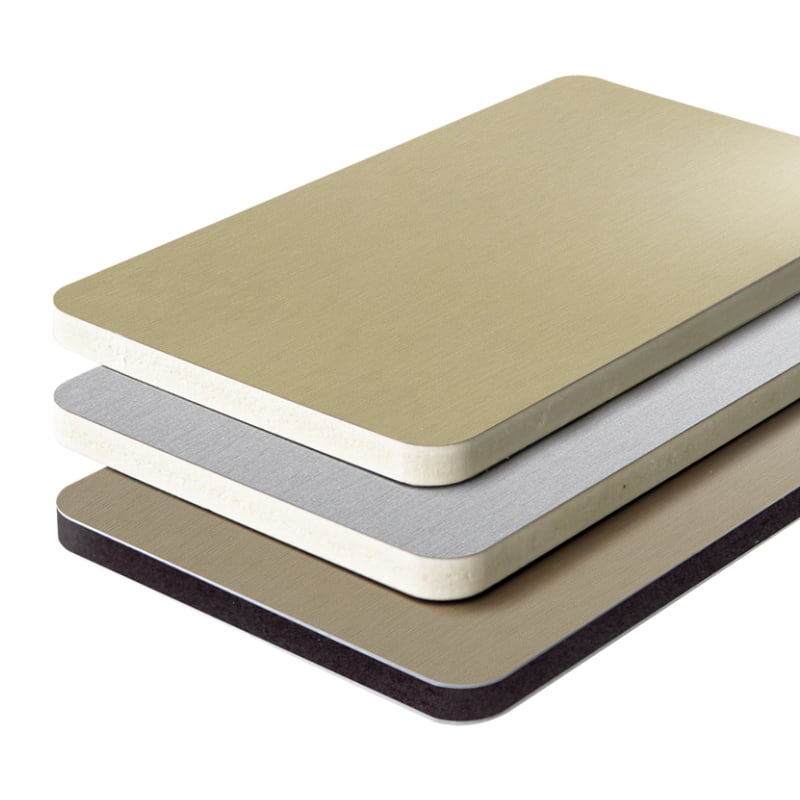

Core Materials and Manufacturing Process

A Carbon Crystal Panel is an advanced engineered building panel designed to optimize multiple performance aspects simultaneously: insulation, structural strength, fire resistance, and durability. Its core comprises carbon-enhanced fibers or crystals embedded within a cementitious or polymer matrix. This unique combination maximizes thermal efficiency, improves mechanical strength, and enhances fire resistance. The manufacturing process involves precise distribution of carbon fibers, high-pressure molding, and controlled curing to ensure homogeneity and stability. By integrating these materials at a microscopic level, Carbon Crystal Panels achieve uniform performance across the panel, outperforming traditional materials like gypsum board or wooden panels in long-term applications.

- Carbon fibers/crystals embedded in cementitious or polymer matrices for reinforcement.

- High-pressure molding ensures dimensional stability and consistent performance.

- Optimized structure enhances thermal insulation, fire resistance, and durability.

- Moisture and termite resistance contribute to long-term reliability.

- Environmentally friendly composition reduces carbon footprint compared to traditional boards.

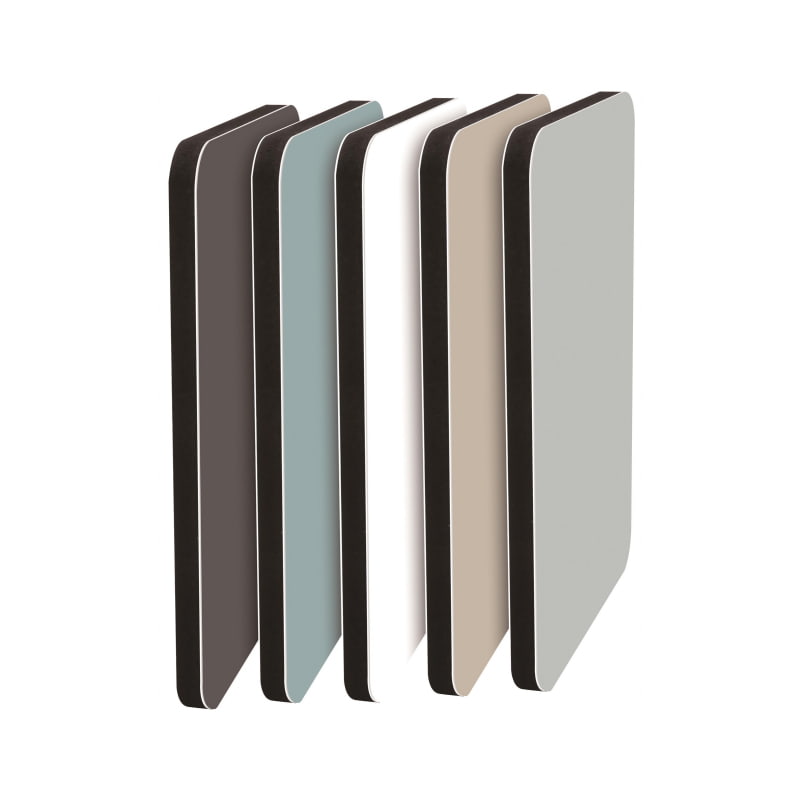

Key Features That Set It Apart

The advantages of Carbon Crystal Panel extend beyond basic functionality. Its low thermal conductivity allows for superior energy efficiency. Structural reinforcement with carbon fibers provides load-bearing capacity suitable for ceilings and multi-story partitions. Fire-retardant components significantly reduce ignition risk and flame spread. Additionally, the panel’s dimensional stability prevents warping, cracking, and moisture-related damage. Its uniformity and precision in manufacturing ensure easier installation, minimal joint issues, and reduced labor time. These combined features make Carbon Crystal Panels an attractive alternative for modern residential, commercial, and industrial applications.

- Superior thermal insulation and energy efficiency.

- High structural strength and load-bearing capacity.

- Fire-resistant for improved safety and compliance.

- Dimensional stability to prevent warping and cracking.

- Resistance to moisture, mold, and pests enhances longevity.

- Precision manufacturing reduces installation complexity and labor time.

The Benefits of Carbon Crystal Panel in Modern Buildings

Enhanced Insulation and Energy Efficiency

One of the most important advantages of a Carbon Crystal Panel is its exceptional insulation capacity. Many searches for “carbon crystal panel wall insulation benefits” indicate that energy efficiency is a primary concern for building owners. The panel’s composite structure significantly reduces heat transfer, keeping indoor environments warmer in winter and cooler in summer. Improved insulation not only lowers energy bills but also maintains consistent indoor temperatures, prevents condensation, and reduces the risk of mold. This efficiency is particularly valuable in climates with extreme seasonal changes. Over the long term, energy savings contribute to reduced carbon emissions, making buildings more environmentally responsible.

- Lower thermal conductivity than traditional drywall or wood panels.

- Reduces heating and cooling costs over the building’s lifecycle.

- Stabilizes indoor temperatures and improves occupant comfort.

- Minimizes condensation and mold growth risks.

- Supports compliance with energy efficiency standards and green building certifications.

Durability and Structural Strength

Durability is a major concern for modern building materials. Many users search for “carbon crystal panel durability compared to gypsum board” to understand long-term performance. Carbon Crystal Panels surpass gypsum board in impact resistance, load-bearing capacity, and environmental resilience. The carbon reinforcement reduces deformation, cracking, and warping over time. Unlike wood or standard drywall, these panels withstand high humidity, temperature fluctuations, and heavy loads. This longevity decreases maintenance frequency and repair costs, particularly beneficial in commercial buildings, high-traffic areas, or multi-story constructions.

- Enhanced load-bearing capacity for ceilings and heavy partitions.

- Resistant to impact, deformation, and cracking.

- Stable performance in high-humidity or variable-temperature environments.

- Reduced long-term maintenance and replacement expenses.

- Ideal for high-traffic commercial, educational, and residential buildings.

Fire Resistance and Safety

Fire safety is a critical factor in modern construction. Many users seek “carbon crystal panel fire resistance rating” to assess safety compliance. Carbon Crystal Panels integrate fire-retardant materials and carbon reinforcement, making them resistant to ignition and limiting flame propagation. Compared to wood panels or gypsum boards, these panels maintain structural integrity under high temperatures and produce less smoke. Their use in multi-unit residential, commercial, or industrial buildings enhances safety, ensures regulatory compliance, and may reduce insurance premiums. Fire-resistance testing often confirms their superior performance relative to traditional alternatives.

- Resistant to ignition and slows flame spread.

- Maintains structural integrity under heat exposure.

- Produces less smoke during combustion.

- Helps meet or exceed building fire-safety codes.

- Enhances occupant safety in public and residential buildings.

Environmental and Sustainability Benefits

Sustainability is increasingly important in construction. Carbon Crystal Panels are often produced using low-emission processes and recyclable materials, reducing environmental impact. Lightweight yet durable, they reduce transportation energy and material waste. Additionally, better insulation lowers the energy demand of buildings, indirectly reducing carbon emissions over the lifecycle. Incorporating these panels supports green building certifications and demonstrates environmental responsibility to stakeholders and occupants.

- Eco-friendly materials with low carbon footprint.

- Reduced energy demand through superior insulation.

- Lightweight panels minimize transportation and handling energy.

- Durability decreases the frequency of replacements, reducing material waste.

- Supports LEED or other green building certifications.

Practical Considerations: Installation, Costs, and Feasibility

Installation Overview

Many builders ask “how to install carbon crystal panel ceiling.” Installation mirrors conventional drywall methods but requires attention to weight and support. Panels should be cut precisely, mounted on suitable framing, and secured with appropriate fasteners. Due to high dimensional stability, joint gaps are minimized, and finishing is smoother. Professional installers adapt quickly, while smaller projects can be managed by trained contractors. The combination of easy adaptation and long-term stability makes installation manageable and predictable.

- Compatible with standard cutting tools and methods.

- Requires proper framing and robust fasteners for ceilings or partitions.

- Dimensionally stable panels ensure clean joints and minimal gaps.

- Faster installation with fewer adjustments compared to warping-prone materials.

- Professional guidance ensures optimal alignment and load distribution.

Cost Analysis

Cost is often searched as “cost of carbon crystal panel per square foot.” While initial investment is higher than traditional drywall, the lifecycle value is substantial. Reduced energy bills, lower maintenance costs, fire compliance savings, and long-term durability offset upfront expenses. Over time, the total cost of ownership can be lower than conventional options, particularly for commercial or high-occupancy projects. Decision-making should factor in energy efficiency, safety, longevity, and sustainability rather than initial price alone.

- Higher upfront cost compared to standard drywall or wood panels.

- Energy savings reduce operational expenses over the building’s life.

- Long-term durability minimizes repair and replacement costs.

- Fire-resistant properties may lower insurance premiums.

- Total lifecycle cost is often more favorable than conventional materials.

Application Scenarios

Carbon Crystal Panels are suitable for a wide range of applications. In residential buildings, they enhance comfort, energy efficiency, and indoor air quality. Commercial offices benefit from fire safety, noise reduction, and durability under high foot traffic. Schools, hospitals, and public buildings require reliable fire resistance and low-maintenance solutions. Industrial facilities gain from structural stability and resistance to moisture or chemical exposure. Overall, Carbon Crystal Panels provide a versatile solution adaptable to nearly every construction context.

- Residential walls, ceilings, and partitions for enhanced comfort and energy efficiency.

- Commercial office spaces for durability, fire safety, and sound insulation.

- Educational and healthcare facilities requiring long-lasting, safe, and low-maintenance materials.

- Industrial buildings benefiting from moisture resistance, structural stability, and easy cleaning.

- Multi-story buildings where load-bearing capacity and fire compliance are critical.

FAQ

Is Carbon Crystal Panel suitable for both walls and ceilings?

Yes. Carbon Crystal Panel offers sufficient load-bearing capacity and dimensional stability for walls and ceilings. Proper installation ensures long-term performance without sagging, warping, or degradation.

How does Carbon Crystal Panel compare to traditional drywall in terms of energy savings?

Due to its low thermal conductivity, Carbon Crystal Panel significantly reduces heating and cooling energy use. Stable indoor temperatures and reduced condensation contribute to lower maintenance costs and improved occupant comfort.

Are there fire‑resistant certifications or standards for Carbon Crystal Panel?

Yes. Many panels are tested for fire resistance and comply with local building codes. They resist ignition, slow flame spread, and maintain structural integrity under heat, offering superior safety compared to gypsum or wood panels.

Does installing Carbon Crystal Panel require special tools or professional installers?

Installation is similar to conventional drywall but may require stronger fasteners and proper framing. Professional installers are recommended for large-scale or structural projects, while trained contractors can handle smaller applications efficiently.

What is the expected lifespan of a Carbon Crystal Panel?

Carbon Crystal Panels can last 25–50 years, depending on environmental conditions and usage. Their resistance to moisture, pests, and fire ensures longevity and reduces replacement and maintenance costs compared to traditional materials.

EN

EN English

English  русский

русский  Español

Español  عربى

عربى