The Ultimate Guide to PVC Decorative Film: Versatility, Application, and Value

In the dynamic world of surface design and manufacturing, PVC Decorative Film stands as a cornerstone material, offering an unparalleled combination of aesthetics, durability, and cost-effectiveness. This versatile film is engineered to transform ordinary surfaces into visually stunning and resilient finishes. From furniture and cabinetry to wall panels and commercial fixtures, its application is vast. Understanding its composition, variations, and benefits is key to unlocking its full potential for any project. This guide will explore the core aspects of PVC Decorative Film, including specialized forms like Lamination PVC Film and its function as a PVC Overlay.

Core Concepts: Understanding the Terminology

To select the right material for your needs, it's crucial to distinguish between the key terms associated with this product category. Each term highlights a specific aspect of the film's design, construction, or intended use.

| Keyword | Focus & Application |

|---|---|

| PVC Decorative Film | The broad, primary term for any PVC-based film used primarily for its aesthetic qualities. It encompasses a wide range of patterns, textures, and finishes designed to enhance the visual appeal of a surface. |

| Lamination PVC Film | Specifies a film used in a lamination process, where it is bonded to a substrate (like MDF, particleboard, or foam board) under heat and pressure. It creates a durable, integrated surface. |

| PVC Overlay | Emphasizes the film's role as a protective and decorative top layer. It is "overlaid" onto an existing surface to provide a new finish, protection from wear, and a refreshed appearance. |

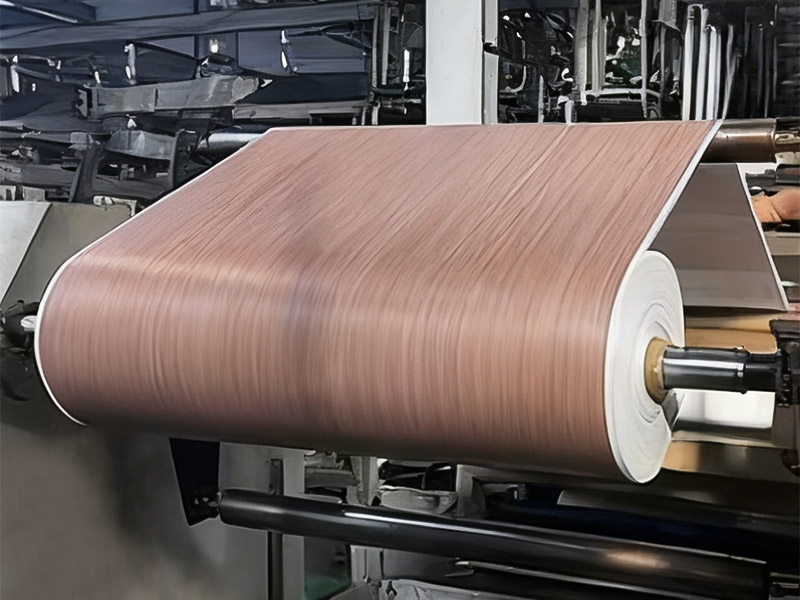

What is PVC Decorative Film and How Is It Made?

PVC Decorative Film is a multi-layered flexible material whose core component is polyvinyl chloride (PVC) resin. Its construction is a sophisticated process designed to achieve both beauty and performance. The typical layers include a base PVC layer for stability, a printed layer that provides the color and pattern (e.g., wood grain, stone, solid color), a transparent wear layer for protection, and an adhesive backing for application. Advanced manufacturing techniques, such as high-resolution printing and embossing, are used to create incredibly realistic textures and patterns, making it difficult to distinguish from natural materials.

Key Characteristics of PVC Decorative Film:

- Design Versatility: Available in an immense library of patterns, including realistic wood grains, marble, abstract designs, and solid colors.

- Surface Durability: The protective wear layer resists scratches, stains, and fading, ensuring the surface looks new for longer.

- Cost Efficiency: Provides the high-end look of expensive materials at a fraction of the cost, reducing material and labor expenses.

- Easy Application: Can be applied using adhesives or through a lamination process, offering flexibility for different manufacturing and renovation methods.

The Role of Lamination PVC Film in Manufacturing

Lamination PVC Film is a critical component in the furniture and construction industries. In this context, the film is not just a decorative sticker but an integral part of the final product. It is permanently bonded to substrates like Medium-Density Fiberboard (MDF) or particleboard to create finished products such as furniture components, cabinet doors, and wall panels. The lamination process, which uses heat and pressure, ensures a seamless, bubble-free bond that is highly durable. This method allows manufacturers to produce large volumes of consistently finished products efficiently, with the added benefit of the film protecting the underlying substrate from moisture and physical damage.

Using PVC Overlay for Renovation and Surface Protection

The concept of a PVC Overlay is central to renovation and refurbishment projects. Instead of replacing an entire item—like a kitchen cabinet, an old desk, or a commercial counter—a PVC Overlay can be applied directly over the existing surface. This process is minimally invasive, cost-effective, and significantly faster than full replacement. The overlay serves a dual purpose: it provides an immediate aesthetic upgrade and acts as a protective shield against future wear and tear. For businesses, this means less downtime during renovations, and for homeowners, it offers an affordable path to a refreshed interior without the mess and cost of construction.

Industry Insights: Technical Excellence and Practical Applications

A Technical Deep Dive into PVC Decorative Film: Composition, Manufacturing, and Quality Standards

The performance of PVC Decorative Film is rooted in its technical composition. Key parameters such as PVC resin type, film thickness measured in microns, and the advanced printing technology used—like rotogravure or digital printing—determine the final product's quality. The thickness of the wear layer is a critical factor in abrasion resistance, while compliance with international standards like EN 71, REACH, and RoHS ensures safety and environmental sustainability. With over 20 years of manufacturing expertise, Zhejiang Highsea New Material Co., Ltd. meticulously controls these parameters, delivering premium PVC Decorative Film that meets rigorous global standards for performance and eco-friendliness.

From Substrate to Surface: The Critical Role of Lamination PVC Film in Modern Furniture Manufacturing

In modern furniture manufacturing, Lamination PVC Film is indispensable for creating durable and beautiful finished products. The success of the lamination process depends on several factors: the adhesive performance, including activation temperature and flow; precise lamination temperature and pressure; and the film's compatibility with various substrates like MDF, particleboard, and PVC foam boards. A crucial feature is post-forming ability, which allows the film to be bent around curved edges without cracking. As a specialist in both substrates and decorative films, Zhejiang Highsea New Material Co., Ltd. provides optimized Lamination PVC Film that ensures a strong, seamless bond, enabling manufacturers to produce high-quality furniture with maximum efficiency.

Cost vs. Durability: A Comprehensive Analysis of PVC Decorative Film for High-Traffic Commercial Spaces

For high-traffic commercial environments, selecting a surface material involves a careful analysis of cost versus durability. PVC Decorative Film excels in this area by offering a low total cost of ownership. Key performance indicators include abrasion resistance (measured by the Taber test), chemical resistance to cleaning agents, and lightfastness to prevent fading. High-quality films provide superior impact resistance and maintain their appearance for years, reducing the need for costly replacements. Zhejiang Highsea New Material Co., Ltd. focuses on creating films that are not only aesthetically pleasing but also engineered to withstand the rigors of commercial use, providing clients with a long-lasting, cost-effective solution that protects their investment.

The Ultimate Makeover: Using PVC Overlay for Sustainable and Efficient Interior Renovation

PVC Overlay represents a paradigm shift in interior renovation, prioritizing sustainability and efficiency. Instead of demolishing and disposing of old fixtures, overlays can be applied directly, dramatically reducing construction waste and resource consumption. The effectiveness of an overlay depends on parameters like the type of pressure-sensitive adhesive (PSA), its conformability to corners and curves, and its removability without leaving residue. This makes it perfect for both permanent upgrades and temporary changes in leased spaces. Zhejiang Highsea New Material Co., Ltd. offers customized PVC Overlay solutions that enable architects, designers, and homeowners to achieve stunning transformations quickly and affordably, aligning with modern principles of sustainable design.

Beyond Aesthetics: How PVC Decorative Film Enhances Product Functionality and Brand Identity

PVC Decorative Film transcends mere decoration to become a tool for enhancing functionality and reinforcing brand identity. Advanced capabilities include custom printing with logos and brand colors, applying special finishes like matte, gloss, or textured leather feels, and incorporating functional additives such as antimicrobial or flame-retardant properties. The tactile experience, achieved through sophisticated embossing techniques, can significantly elevate a product's perceived value. Zhejiang Highsea New Material Co., Ltd. excels in this area, offering bespoke solutions that allow clients to integrate their brand directly into the product's surface, creating a cohesive and memorable user experience while adding practical, functional benefits.

FAQ

How durable is PVC Decorative Film compared to real wood or laminate?

High-quality PVC Decorative Film is engineered for exceptional durability, often rivaling or exceeding that of real wood and traditional laminates in specific aspects. Its performance is defined by its wear layer thickness, which provides superior resistance to scratches, stains, and impact. Unlike real wood, it does not warp, crack, or require periodic sealing. Compared to some laminates, high-grade PVC films offer better moisture resistance. The key is selecting a commercial-grade film with a robust wear layer, as supplied by manufacturers like Zhejiang Highsea New Material Co., Ltd., which undergoes strict quality control to ensure long-lasting performance in demanding environments.

Can PVC Decorative Film be used on curved surfaces or complex shapes?

Yes, one of the significant advantages of PVC Decorative Film is its excellent flexibility and conformability. Standard films can adhere to gentle curves, but for complex shapes and tight radius bends, a specially designed Post-Forming or Heat-Forming PVC film is required. These films are engineered to become pliable when heated, allowing them to be stretched and molded around intricate profiles, such as cabinet doors with routed edges or curved furniture components, without cracking or whitening. This makes them an ideal choice for manufacturers looking to achieve seamless, high-end finishes on complex designs.

Is PVC Decorative Film environmentally friendly and safe for indoor use?

The environmental and safety profile of PVC Decorative Film has improved significantly. Reputable manufacturers prioritize using eco-friendly formulations that are phthalate-free and low in volatile organic compounds (VOCs). Furthermore, leading products comply with stringent international safety and environmental standards like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals). When sourcing from a responsible company like Zhejiang Highsea New Material Co., Ltd., which is dedicated to environmental sustainability, you can be confident that the film is safe for indoor residential and commercial applications and manufactured with a reduced environmental impact.

What is the difference between using a PVC Overlay and a Lamination PVC Film?

The primary difference lies in the application method and the intended permanence. A Lamination PVC Film is used in a manufacturing process where it is permanently bonded to a substrate like MDF under heat and pressure, creating a new, solid composite material. This is ideal for mass-produced furniture and panels. A PVC Overlay, on the other hand, typically features a pressure-sensitive adhesive and is applied post-manufacturing, much like a large, durable sticker. It is primarily used for renovation, refurbishment, and on-site customization, offering a faster and less invasive way to update an existing surface without replacing the entire item.

How do you clean and maintain surfaces finished with PVC Decorative Film?

Maintaining surfaces finished with PVC Decorative Film is remarkably simple, contributing to its popularity. For routine cleaning, a soft cloth or sponge with mild soap and water is sufficient to remove most dirt and smudges. It is important to avoid abrasive cleaners, scouring pads, or solvents, as these can damage the protective wear layer and dull the finish. For more stubborn stains, a gentle, non-abrasive household cleaner can be used. The film's inherent resistance to moisture and stains means that with proper care, the surface will maintain its original beauty for many years, requiring minimal upkeep.

EN

EN English

English  русский

русский  Español

Español  عربى

عربى