From Material to Aesthetics: The Production Process and Quality Control of Vinyl Decorative Film

The journey of creating a high-quality Vinyl Decorative Film is a sophisticated blend of material science and artistic vision. At Zhejiang Highsea New Material Co., Ltd., our over 20 years of manufacturing expertise are poured into every roll, ensuring a product that not only meets but exceeds global standards. This process transforms raw PVC into a durable, beautiful, and versatile medium for interior design.

Core Production Stages

The manufacturing of premium decorative film involves several critical stages, each meticulously controlled to guarantee the final product's integrity.

1. Raw Material Preparation

The foundation of any great product is its inputs. We begin by sourcing high-grade PVC resin, eco-friendly plasticizers, and advanced stabilizers. The precise formulation of these materials dictates the film's flexibility, durability, and environmental safety.

2. Mixing and Calendaring

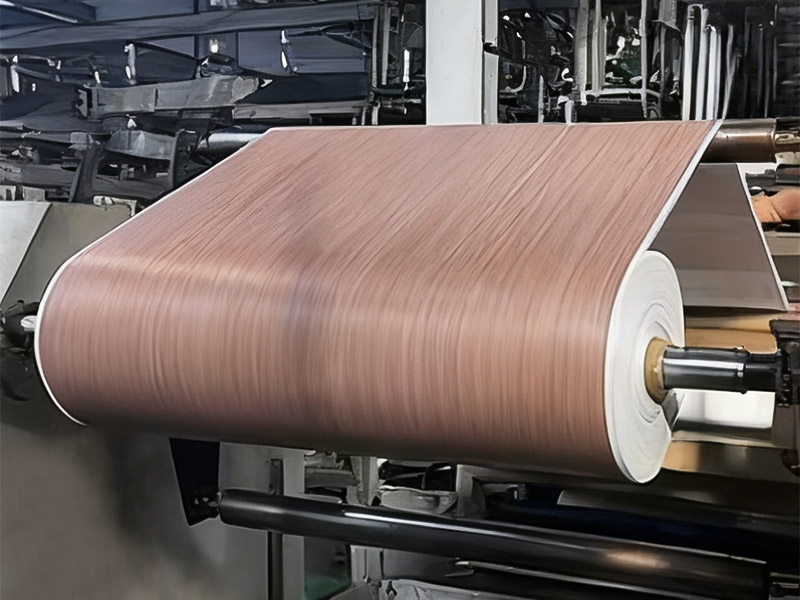

The raw materials are compounded in a high-speed mixer to create a uniform PVC compound. This compound is then fed into a calendaring machine, where it is pressed between large, heated rollers to form a thin, uniform vinyl sheet of the desired thickness.

3. Printing and Embossing

This is where aesthetics come to life. Using state-of-the-art rotogravure printing technology, high-resolution patterns and colors are applied to the vinyl sheet. Following printing, the film can be embossed, adding texture and depth that mimic natural materials like wood grain or stone.

4. Adhesive Application and Lamination

For self-adhesive products, a pressure-sensitive adhesive layer is precisely applied to the back of the printed film. A release liner is then laminated over the adhesive to protect it until installation. A clear, protective wear layer is often applied on top to enhance scratch and stain resistance.

Rigorous Quality Control Parameters

Quality is not an act; it is a habit. Throughout the production process, our QC team conducts rigorous tests based on the following parameters:

- Thickness Tolerance: Measured with precision instruments to ensure uniformity across the entire roll, typically within a tolerance of ±0.02mm.

- Color Fastness: Tested against standards like ISO 105-B02 to ensure resistance to fading from light exposure.

- Adhesion Strength: The adhesive's performance is tested on various substrates to ensure a strong, lasting bond without leaving residue upon removal.

- Environmental Compliance: We verify that our products are phthalate-free and have low VOC emissions, complying with regulations such as REACH and RoHS.

- Fire Rating: Films are tested to achieve flame-retardant ratings like B1, ensuring safety for interior applications.

Breaking the Mold: Achieving Differentiated Commercial Design with Other PVC Decor Film

In today's competitive market, standing out is paramount. Standard designs no longer capture attention. This is where Other PVC Decor Film becomes a powerful tool for architects, designers, and brand owners. These specialty films move beyond conventional patterns, offering unique textures, abstract graphics, and bespoke visuals that create memorable commercial spaces.

The Power of Unique Surfaces

Specialty decorative films allow for the creation of environments that evoke specific emotions and brand identities. A boutique hotel might use a film with a subtle, metallic texture to convey luxury, while a modern tech office could employ abstract geometric patterns to foster creativity. The key is differentiation.

Applications in Commercial Spaces

- Retail Environments: Create stunning feature walls, custom fixture wraps, and unique entryways that draw customers in.

- Hospitality Sector: Design headboards, bar fronts, and elevator interiors that provide a high-end, custom feel without the custom price tag.

- Corporate Offices: Use branded patterns or inspiring textures in reception areas, conference rooms, and collaborative zones to reinforce company culture.

Tailored Solutions from Zhejiang Highsea

Our strength lies not just in our product range but in our ability to provide customized recommendations. We work closely with clients to understand their project requirements, from concept to completion, ensuring the selected Other PVC Decor Film delivers optimal performance and style integration. Our manufacturing flexibility allows for custom color matching and pattern development, bringing a unique vision to life.

DIY vs. Professional Installation: Mastering Self Adhesive PVC Decorative Film

The popularity of Self Adhesive PVC Decorative Film stems from its accessibility. Whether you are a seasoned DIY enthusiast or a professional contractor, understanding the correct installation techniques is crucial for achieving a flawless, long-lasting finish. This guide breaks down the process and highlights common pitfalls to avoid.

Essential Preparation for a Perfect Application

Surface is Everything

The success of your project is 90% preparation. The target surface must be:

- Smooth: Free from cracks, bumps, and imperfections. A 2-meter straightedge should not reveal more than a 2mm gap.

- Clean: Wiped down with a mild detergent to remove all dust, grease, and grime. Residue will prevent proper adhesion.

- Dry: Completely dry to the touch. Moisture trapped under the film will cause bubbles and can compromise the adhesive.

Required Tools

Gather your tools beforehand: a sharp utility knife with extra blades, a measuring tape, a squeegee (or a plastic card), and a heat gun or hairdryer for corners and contours.

Step-by-Step Installation Guide

- Measure and Cut: Measure the area precisely and cut the film, leaving a slight overlap on all edges for trimming.

- Position and Peel: Position the film on the surface. Peel back about 10-15 cm of the backing paper.

- Apply and Smooth: Stick the exposed edge to the surface. Use the squeegee to press the film down, working from the center outwards to push out air. Gradually peel more of the backing as you go.

- Trim the Excess: Once the film is fully applied, use the utility knife to trim the excess material for a clean edge.

Common Mistakes and How to Avoid Them

- Air Bubbles: Caused by rushing the application. Always smooth from the center out. Small bubbles can be pricked with a pin and smoothed out.

- Wrinkles: Often a result of misalignment. If a large wrinkle forms, gently lift the film and reapply. Do not stretch the film.

- Lifting Edges: Usually due to a dirty or damp surface during installation. Ensure the area is perfectly prepared.

A Comprehensive Guide to PVC Decorative Materials: Coordinating Films, Panels, and Flooring

Creating a cohesive interior design requires a holistic approach to materials. Zhejiang Highsea New Material Co., Ltd. offers a complete suite of PVC decorative solutions, including Vinyl Decorative Film, PVC wall panels, and PVC flooring. Understanding how to coordinate these products allows for the creation of unified, stylish, and functional spaces with consistent quality and performance.

The Principle of Material Synergy

When used together, our PVC products create a harmonious environment. For instance, a wood-grain pattern from our decorative film collection can be perfectly matched with our PVC wall panels and flooring in the same or a complementary tone. This synergy simplifies the design process and ensures a professional, integrated look.

Strategic Application for Optimal Performance

Different areas of a room have different functional demands. A strategic approach to material placement is key.

- High-Traffic Floors: Use our durable PVC flooring, which is designed to withstand heavy foot traffic, scratches, and spills.

- Accent Walls & Ceilings: PVC wall panels offer quick, seamless coverage and can hide wall imperfections while adding texture.

- Furniture & Fixtures: Apply Vinyl Decorative Film to cabinets, doors, and built-in furniture to tie the entire room's color scheme together without the cost of replacement.

Cost-Effective and Sustainable Design

By coordinating PVC materials, designers can achieve a high-end look for a fraction of the cost of using natural materials like solid wood or stone. Furthermore, all our products are manufactured with a focus on sustainability, being low in VOCs and fully recyclable, contributing to greener building practices.

FAQ

How durable is self-adhesive vinyl decorative film for high-traffic areas like kitchens?

The durability of Self Adhesive PVC Decorative Film in high-traffic areas depends on its quality and construction. Our films are manufactured with a protective wear layer that enhances resistance to scratches, scuffs, and stains. For kitchens, we recommend films with a thicker wear layer and a matte or textured finish, as these are better at hiding minor imperfections and are easier to clean. While highly durable, it is important to avoid placing hot pots and pans directly on the surface. With proper installation and care, our films can last for many years, even in a busy kitchen environment.

Can Vinyl Decorative Film be applied to textured surfaces like orange peel walls?

Applying Vinyl Decorative Film to a textured surface is not recommended for a flawless finish. The adhesive is designed to bond to a completely smooth surface. Textures like orange peel or knockdown will create air pockets, preventing the film from adhering properly and resulting in a bumpy, unprofessional appearance. For best results, the wall should be skim-coated with joint compound, sanded smooth, cleaned, and primed before applying the film. This preparation ensures a strong bond and a smooth, flat final look.

What is the best way to remove air bubbles from a large sheet of Other PVC Decor Film?

Prevention is the best method when working with Other PVC Decor Film. Always apply the film using a squeegee, starting from the center and pushing outwards to expel air as you go. However, if you find a trapped air bubble after installation, you have two options. For a small bubble, you can prick it gently with a fine pin at the edge, press out the air, and then smooth the area. For a larger bubble, it's often better to gently lift the film back to the point of the bubble, re-smooth the area, and then re-lay the film down. Avoid using excessive force, as this can stretch the film.

Is PVC decorative film, including wall panels and films, environmentally friendly?

Yes, modern PVC decorative materials can be an environmentally friendly choice, and this is a key focus for Zhejiang Highsea. Our products, including our Vinyl Decorative Film and wall panels, are manufactured to be phthalate-free and have low VOC (Volatile Organic Compound) emissions, ensuring better indoor air quality. Furthermore, PVC is a highly durable material, meaning products made from it have a long lifespan, reducing the need for frequent replacement and the waste associated with it. At the end of their life, PVC products are also recyclable, contributing to a circular economy.

EN

EN English

English  русский

русский  Español

Español  عربى

عربى