Understanding PVC Hot Stamping Foil Rolls: Technology, Application, and Selection

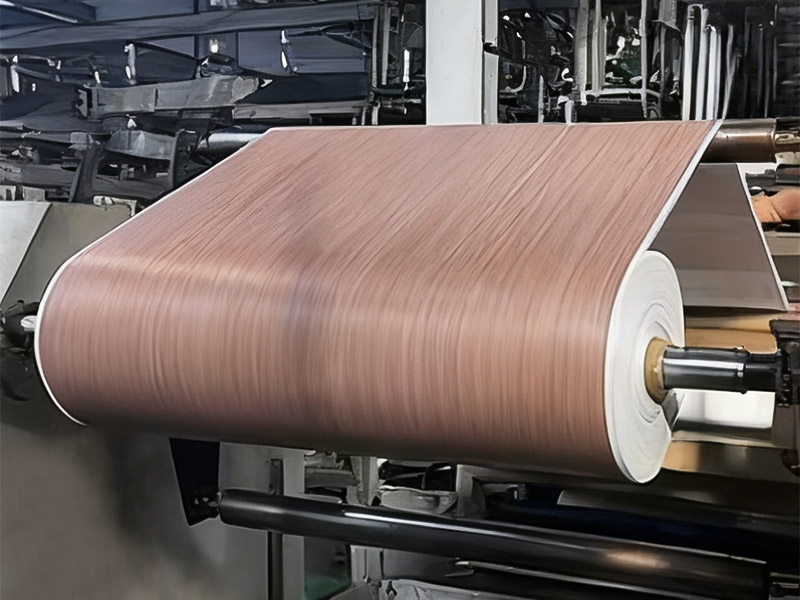

In the world of advanced surface decoration,PVC Hot Stamping Foil Roll stands as a critical technology for applying durable, high-quality metallic, pigment, and special-effect finishes. Also known commercially as Hot Stamping PVC Film or PVC Heat Transfer Film, this material enables manufacturers across industries—from interior décor to luxury packaging—to enhance product value and aesthetics. For a specialized producer like Zhejiang Highsea New Material Co., Ltd., with deep expertise in PVC-based solutions, mastering the nuances of hot stamping film is key to delivering finishes that are not only visually striking but also performance-driven and environmentally considered.

What is a PVC Hot Stamping Foil Roll?

A PVC Hot Stamping Foil Roll is a multi-layer laminate supplied on a roll, designed for transfer onto a substrate using heat and pressure. The process involves a heated die pressing the foil against the surface, causing the release layer to detach and the decorative layer to bond permanently. This method is distinct from printing, as it deposits a physical layer of material—be it metallic, colored, or holographic—resulting in superior opacity, scratch resistance, and a tactile quality that ink cannot replicate.

Key Applications and Advantages

Hot stamping foil is prized for its versatility and premium finish. Its primary applications include:

- Interior Decorative Surfaces: Enhancing PVC wall panels, ceiling panels, and furniture foils with woodgrain, metallic, or custom patterns.

- Packaging: Creating eye-catching, luxury finishes on cosmetic boxes, beverage labels, and gift packaging.

- Consumer Electronics: Applying brand logos, decorative accents, and tactile indicators on device casings.

- Automotive Interiors: Adding durable, glossy, or matte accents to trim components.

- Promotional and Signage Items: Producing awards, nameplates, and retail signage with a high-value appearance.

Core Benefits

- Exceptional Durability: Resistant to abrasion, chemicals, and fading for long-lasting aesthetics.

- Brilliant Opacity: Achieves full, vibrant coverage even on dark-colored substrates.

- Design Flexibility: Available in a vast spectrum of colors, effects (metallic, pearl, matte), and custom holographic patterns.

- Process Efficiency: Offers a clean, dry finishing method with no drying or curing time, increasing production speed.

- Enhanced Product Value: Instantly elevates the perceived quality and luxury of the finished product.

Technical Specifications and Selection Guide

Selecting the correct foil requires matching its technical properties to the substrate and end-use requirements. The following table outlines common types:

| Foil Type | Primary Use | Key Characteristics |

| Metallic Foil (Gold, Silver, Copper) | Luxury packaging, decorative accents | High gloss, excellent reflectivity, classic premium look |

| Pigment Foil | Brand logos, text on dark backgrounds | Solid, opaque colors, high durability, wide color gamut |

| Holographic / Diffractive Foil | Security features, promotional items | Dynamic light reflection, complex patterns, brand protection |

| Matte & Soft-Touch Foil | High-end electronics, cosmetic packaging | Elegant non-reflective finish, tactile sophistication |

| Special Effect Foil (Pearl, Chrome) | Automotive, premium consumer goods | Unique visual depth, high-tech appearance |

How to Choose the Right Foil

Making the optimal selection involves evaluating several factors:

- Substrate Material: The foil's adhesive layer must be compatible with the surface (e.g., PVC, ABS, paper, coated metals). Always conduct adhesion tests.

- End-Use Environment: Consider exposure to UV light, moisture, abrasion, or chemicals. Outdoor applications demand foils with UV inhibitors and superior weatherability.

- Production Parameters: Match the foil's release temperature and speed rating to your hot stamping machine's capabilities.

- Regulatory Compliance: For toys, food packaging, or other sensitive applications, ensure the foil meets relevant safety standards (e.g., FDA, REACH, EN 71).

Industry Trends and Future Outlook

The hot stamping foil industry is evolving to meet new market demands:

- Sustainability: Development of foils with bio-based carriers, recyclable layers, and solvent-free adhesives.

- Digital Integration: Hybrid processes combining digital printing with selective foil stamping for mass customization.

- Advanced Functionality: Foils with integrated smart features, such as conductive traces for printed electronics.

- Textured and 3D Effects: Films that create not only visual but also tactile surface textures during transfer.

FAQ

What is the main difference between hot stamping foil and cold foil transfer?

The core difference lies in the application process and adhesive activation. Hot stamping foil requires a heated die to activate a heat-sensitive adhesive layer on the foil, bonding it under pressure. It is ideal for complex shapes, offers brilliant metallics, and is highly durable. Cold foil transfer uses a UV-curable adhesive printed onto the substrate first; the foil is then laminated and only bonds where the adhesive is present. Cold foiling is faster and better for inline digital printing but typically offers slightly less metallic brilliance and durability than hot stamping. The choice depends on production speed, budget, and the required finish quality.

Can PVC hot stamping foil be used on food contact packaging safely?

Yes, but only if the specific foil grade is certified for food contact. Reputable manufacturers offer foils compliant with regulations like FDA CFR 21 in the USA or EU Framework Regulation (EC) No 1935/2004. These foils are formulated with ingredients that do not migrate into food in harmful quantities. It is crucial to request and verify the supplier's compliance statements or migration test reports. The suitability also depends on the type of food and whether the packaging is for direct or indirect contact.

Why is my hot stamping foil not adhering properly to PVC substrates?

Poor adhesion on PVC or other plastics can stem from several issues. First, ensure you are using a foil specifically engineered for plastics; foils for paper will fail. The top causes include:

- Incorrect Temperature/ Pressure: Too low prevents adhesive activation; too high can degrade the substrate or adhesive.

- Subsurface Contamination: Mold release agents, oils, or dust on the PVC surface create a barrier. Pre-cleaning with isopropyl alcohol is essential.

- Incompatible PVC Formulation: Some PVC blends contain plasticizers that can migrate to the surface, inhibiting bond formation. A test run is always recommended.

- Die Issues: An uneven or worn die will apply inconsistent pressure.

Systematic testing of process parameters is key to troubleshooting.

How does the durability of a hot-stamped finish compare to screen printing or digital printing?

Hot stamping generally offers superior mechanical and chemical durability. The transferred layer is a solid, often metallic or pigmented film, making it highly resistant to abrasion, scratching, and many solvents. Screen printing uses layers of ink that can crack or wear. Digital prints, while high-resolution, typically have a thinner ink layer vulnerable to wear unless over-laminated. For applications requiring a premium feel and long-term wear resistance—such on PVC wall panels in high-traffic areas or frequently handled tools—hot stamping is often the preferred choice.

Are there environmentally friendly options for hot stamping foils?

Absolutely. The industry is actively developing greener solutions. Key advancements include:

- PVC-Free Constructions: Foils using polyester or other alternative carriers that are more easily recycled.

- Water-Based Release Layers: Replacing solvent-based systems to reduce VOC emissions.

- Thinner Metallization: Using advanced vacuum metallurgy to achieve the same visual effect with less aluminum, reducing material use and improving recyclability of stamped paper products.

- Bio-Degradable Components: Research into compostable layers for specific applications.

When sourcing, ask suppliers for information on the foil's recyclability compatibility and environmental certifications.

EN

EN English

English  русский

русский  Español

Español  عربى

عربى